Why Cannabis Hemp In Puerto Rico Could Be The New Sugar Cane

I am currently living in the beautiful tropical island, Puerto Rico and I look at the potential this beautiful island has to be productive. An beautiful paradise with rich fertile land and tropical warm weathers all year long. Yet they produce very little here as they don’t have no major industries. About 85 percent of the food is also imported.

Coffee, tobacco and sugar cane were the primary income crops from the time the island was ‘settled’ until well into the 20th century.

In 1942 the hypocritical US government made a film entitled hemp for victory in 1942 encouraging farmers to grow hemp for the war. The film can be seen here.

Brief history on the sugar cane industry in PR

The cultivation of sugar cane and the production of sugar largely forged the local and international identity of Puerto Rico until the 20th century. According to historical documents, the first farms producing the sweetener date to the 16th century. These sugar mills were known locally as ingenios or trapiches. In 1523, Genovese native Tomás de Castellón established in San Germán the first sugar mill, called San Juan de las Palmas. Others were founded in the 1540s along the banks of navigable rivers near San Juan. From the late 17th century on, huge extensions of land were dedicated to commercial agriculture. Those dedicated to raising sugar cane were called haciendas azucareras, the sugar plantations.

During the first decades of the 20th century, the sugar industry continued to develop and reached its peak. Despite the establishment of huge sugar trading businesses, some mills backed by Puerto Rican capital also showed considerable production capacity. By 1930, there were 44 mills in operation. In the 1940s, however, the mills began to weaken, due to various factors. The fall in the price of sugar, mismanagement by some administrators, the restriction of credit to independent farmers, as well as the strikes by workers, created conflict and conditions that led to the decline and eventual closure of many of the mills in the subsequent decades.

Following the record sugar cane harvest of 1952, the industry experienced an accelerated deterioration. Additionally, the production of sugar took a lower priority as the government undertook to industrialize the island. Between 1951 and 1968, 17 mills ceased operations. At the end of the 1960s, the government tried to rescue the industry through a recovery program. The Land Authority acquired a significant number of mills and in 1973 created the Sugar Corporation. Despite the fact that the government became the principal sugar producer in Puerto Rico, the mills, both privately and publicly funded, were shut down, one by one. In 2000, operations ceased at the last mills still functioning: Roig in Yabucoa and Coloso, which had operated for nearly 100 years in the municipality of Aguada. Some of the mills also included refineries and packaging operations whose refined white sugar, with its fine grain, built the reputation of the Puerto Rican sugar producers as true artisans.

So now what we have is an island with so much unused land. Everything has become a ghost town as you find homes abandoned, as you drive down the town all you find is closed stores with a for rent sign as everyone started supporting the big global chains like walmart.

So what can we do? We must evolve and my solution is cannabis Hemp. A very beneficial plant that has been neglected in most parts of the world due to it being tied to it’s cousin “marijuana”, but one thing people fail to realize is that you can’t smoke cannabis hemp as it has no THC which I will go into detail further.

But here I will list why Cannabis Hemp could be not only Puerto Rico’s cash crop, but for the rest of the world.

Best part of all it’s great for the environment as well and I go listing many reasons why further on this post.

What is Hemp and the difference between Hemp and “Marijuana”?

Hemp is one of the most useful plants on Earth.

For thousands of years, humans have used parts of the hemp plant for food, textiles, paper, fabric, and fuel oil. Today, modern processing technologies have made it possible to create alternatives to gasoline, plastic, and other petroleum products that can help the human race lessen its reliance on polluting and expensive fossil fuels.

Hemp has been grown forever – The plant is so old, so useful, and so reliable. Hemp cloth found in Iran and Iraq has been dated to 8000 B.C. According to MIT:

“Hemp is also believed to be the oldest example of human industry. In the Lu Shi, a Chinese work of the Sung dynasty (500 AD), we find reference to the Emperor Shen Nung (28th century BC) who taught his people to cultivate hemp for cloth. It is believed that hemp made it to Europe in approximately 1,200 BC. From there, it spread throughout the ancient world.”

The hemp plant is a renewable resource that can be produced domestically. It grows quickly, naturally resists plant diseases, requires little weeding, thrives in most climates, and enriches the soil it grows in.

Hemp is a close cousin to marijuana, but it isn’t the same. Both come from the plant Cannabis Sativa L. but industrial hemp contains only about 0.3% – 1.5% Tetrahydrocannabinols (THC) – the compound responsible for the ‘high’.

Both cannabis Hemp and Cannabis have noticeable levels of CBD, which is beneficial in many medical applications. Many experts, however, believe that CBD derived from Cannabis “Marijuana” can be more effective.

Industrial hemp is a variety of cannabis sativa that has a long history of use in the United States.

However, since the 1950s it has been lumped into the same category of marijuana, and thus the extremely versatile crop was doomed in the United States.

The many uses of cannabis hemp

Paper products

It takes years for trees to grow until they can be harvested for paper or wood, but hemp is ready for harvesting only 120 days after it is planted. Hemp can grow on most land suitable for farming, while forests and tree farms require large tracts of land available in few locations. Harvesting hemp rather than trees would also eliminate erosion due to logging, thereby reducing topsoil loss and water pollution caused by soil runoff.

There are 4 characteristics of hemp which make it particularly appealing for making paper:

- Hemp fibers are long (makes for stronger paper which can be recycled more times than wood paper)

- Hemp contains high levels of cellulose (57-77% – more cellulose makes for more pulp)

- Hemp has low (3%) lignin content (this is what makes wood-pulp paper turn yellow over time).

- One acre of hemp can produce as much usable fiber as four acres of trees. Hemp can be harvested every 100 days. Trees take decades to harvest.

The best part about hemp-based paper is that its production is environmentally friendly. Wood paper? Not so much…

Because of both its chemical and physical composition, hemp can produce high pulp yields and can be pulped without use of the Kraft process (used for chemical pulping of wood and long-fiber specialty papers) which uses sulfur compounds that are environmentally toxic. Also, as with other non-wood pulp, hemp can be bleached with peroxide and through other processes that do not involve chlorine.

– “Illegally green: Environmental Costs of Hemp Prohibition“, The Reason Foundation – Skaidra Smith-Heisters

Clothing and textiles

Another use of hemp that has dates back thousands of years is the creation of clothing and textiles from its fibres. These have ranged from strong, durable rope, to comfortable soft garments. It only fell out of mainstream use due to the pressure from the cotton and synthetic fibre industry. There is no good reason for not making hemp clothing, and anything that can be made with cotton can be made just as nicely with hemp – but with considerably less environmental impact.

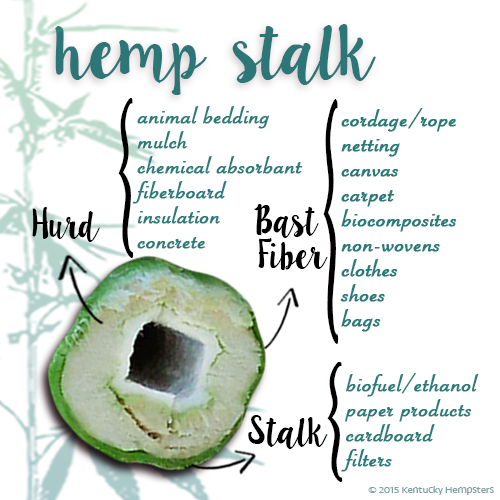

There are two main types of fibres within hemp plants, known as bast fibres (long, made of the plant stem) and the hurds (the short inner fibres of the stem). It is the bast fibres that are best suited to the production of textiles, and account for 20 – 30 percent of a hemp plant stem. It was the need for these fibres that largely fueled the hemp industry before it was prohibited.

The long bast fibres can be split further into two groups. These are primary and secondary bast fibres.

Primary bast fibres are extremely long, high in cellulose and low in lignin – making them some of the strongest plant fibres known to man. They account for up to 70 percent of the bast fibres present within a hemp stem, and were traditionally the most valued.

Secondary bast fibres, whilst useful, were less valued. They are much shorter than primary bast fibres but still have a high cellulose and low lignin levels. They are prevalent in crops that are spaced out, causing hemp plants to grow squatter as they have little competition for sun.

Both of these fibre types can be turned into soft, comfortable, yet durable clothing. Furthermore, according to research conducted by the Stockholm Environment Institute, hemp requires half the land, less chemical fertilisers and less water than cotton requires to produce textiles of the same quality – making it a much more environmentally harmonious choice. Throughout much of civilised history, hemp was the main source for textiles. For millennia, 90% of all ships sails and ropes we made from hemp.

Cotton is an extremely destructive crop, taking up 50% of the world’s pesticide stock to grow. It is pesticides that are responsible for the dying of the bees, deteriorating quality of soil and water; they are also potent carcinogens, which often find their way into the food chain and finally end up in humans. Conversely, hemp can be grown organically without pesticides as it is an extremely resilient plant; furthermore, this resilience allows hemp to be grown pretty much in any condition. Hemp has further been found to improve the soil quality, particularly when used in a crop rotation system. Cotton on the other hand requires very specific growing conditions, and a great deal of water.

There is one country that still uses hemp for clothing, and that is China. China has not put the same restrictions on hemp as the rest of the world, and as a result has had over 6,000 years of producing safer, softer and more comfortable textiles.

Building Materials

Nearly every part of a house construction can be done using hemp products. Hemp can be made into bricks, concrete, wall boards and plaster. Pipes can be made out of hemp plastic, carpet can be made out of hemp, insulation can be made out of hemp, and even paint can be made from hemp oils. The versatility hemp offers as a green resource is staggering.

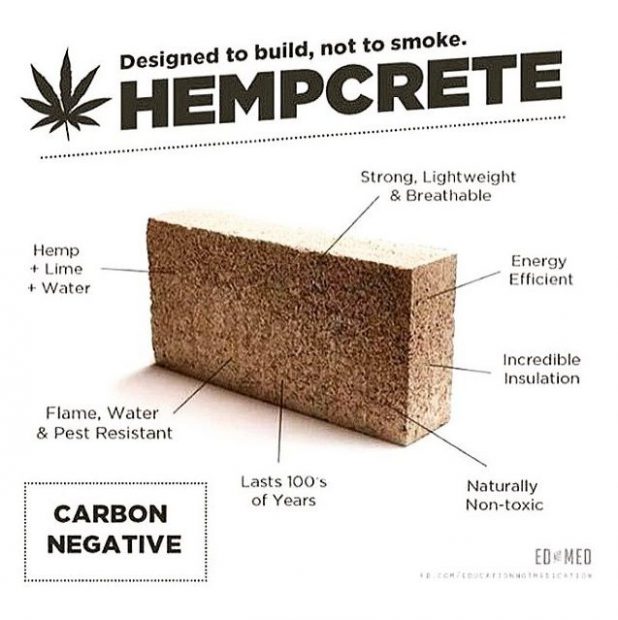

The short inner fibers of hemp are called hurd; these are combined with lime to give a material that is commercially known as Hempcrete or Isochanvre; though this material resembles concrete, it is half its weight and thrice as elastic. Hempcrete blocks are used as an insulating material and to control moisture. A building made with Hempcrete blocks will remain warm in the winter and cool in the summer. Although this material is strong, its blocks need to be reinforced by a frame of steel, brick or wood to be used as structural elements in construction. They are not as brittle as concrete and do not need expansion joints for stability. Another good use of hemp is for sound-proofing walls and ceilings of buildings, since it has acoustic insulation properties. Fiberboards are made of the long bast fibers of hemp. They have much more strength and resistance to insects and fire than fiberboards made from wood chips.

Hemp has the potential to revolutionise the building sector and make for much greener housing. All major components of hemp (oils and fibres) can be utilised by builders. These versatile components can be shaped and used to recreate the characteristic of woods, concrete, plastic, bricks, insulation and even panelling.

As things currently stand, it usually costs more to construct a house using hemp products. This is due to the legal status of hemp, meaning that the products can be quite hard to source – and with anything in a capitalist market of supply and demand, if the supply is low, the cost is high. As reform takes place and hemp production increases, we should see an decrease in price of hemp building products.

Walls made from hemp can last up to 500 years. How’s that for sustainability?

Bio fuel

Yes, we’ve all heard of “bio-diesel,” but the really exciting breakthrough isn’t biodiesel. Any vegetable oil can be made into biodiesel. What’s really a game-changer is hemp can be used to make gasoline. The good stuff. Real, unleaded gasoline, identical to the stuff we currently put into our combustion engine vehicles, but derived completely from cellulose.

“Making it from cellulose sources such as Switchgrass or poplar trees grown as energy crops, or forest or agricultural residues such as wood chips or corn stover, solves the lifecycle greenhouse gas problem that has recently surfaced with corn ethanol and soy biodiesel.”

– John Regalbuto, Director of the Catalysis and Biocatalysis Program at The National Science Foundation

“But, that’s ‘wood’ and ‘corn,’” you say, “what does this have to do with hemp“?

Well, it turns out that hemp is the best plant in the world to produce biomass for cellulosic gasoline.

Hemp is the world’s most versatile plant. It can yield 10 tons per acre in four months. Hemp contains 80% cellulose; wood produces 60% cellulose. Hemp is drought resistant making it an ideal crop in the dry western regions of the country.

– “Energy Farming in America“, Lynn Osburn, .

Once this technology has evolved sufficiently to be cost effective at large scales, we conclude that Cannabis sativa and its related species is a superior cultivar for bio-fuel production. Hemp exhibits far superior ethanol yields per unit biomass compared to Zea mays (Corn) or Panicum virgatun (Switchgrass), which are currently the two most supported biofuel cultivars by the United States government.

– “Does the use of Cannabis species for the production of biodiesel and ethanol result in higher yields of ethanol than competing cellulotic crops, including Zea mays?“, University of Washington Dept. of Biology 2008 – Kimball Christensen & Andrew Smith,

Once we get the production of cellulosic gasoline (hopefully supplied by hemp) ramped up to the point that we can start fueling most of our vehicles with it, simply using cellulosic gasoline will reduce our greenhouse gas emmisions (GHG) by 85% compared to today’s reformulated petrol/ethanol-gasolines.

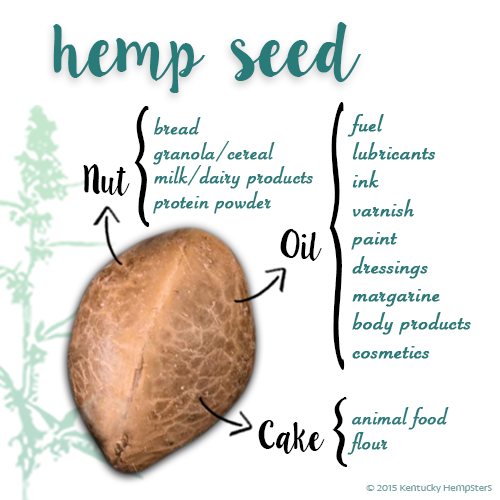

Hemp seeds have provided a combustible fuel oil throughout human history. Basically, hemp can provide two types of fuel:

1. Hemp biodiesel – made from the oil of the (pressed) hemp seed.

2. Hemp ethanol/methanol – made from the fermented stalk.

Food

Hemp is cheap to grow, and it grows almost everywhere. So we could grow a whole lot of it for very little. And while where were using all that cellulose from hemp’s biomass to make gasoline and clothes and better materials for our homes, we could be using the seeds for food.

It is a great protein source, and is a vegetable-based source of all nine essential amino acids. Hemp seed protein is 65% globulin edistin, and also includes quantities of albumin. What’s more, its protein is readily available in a form quite similar to that found in blood plasma. It also contains important fatty acids, vitamin E, many trace minerals, and has the perfect Omega 3 to Omega 6 ratio of 3 to 1, which can help keep your fatty acid balance on target. Hemp is highly digestible, unlike soy, and can help heal people from immunity disorders.

Hemp seeds are not intoxicating. Hemp seed protein can be used to produce virtually any product made from soybean: tofu, veggie burgers, butter, cheese, salad oils, ice cream, milk, etc. Hemp seed can also be ground into a nutritious flour that can be used to produce baked goods such as pasta, cookies, and breads.

That’s right: hemp seed is a food, and a really great food at that.

From Wikipedia:Hemp seed’s amino acid profile is “complete” when compared to more common sources of proteins such as meat, milk, eggs and soy. Hemp protein contains all nutritionally significant amino acids, including the 9 essential ones[12] adult bodies cannot produce. Proteins are considered complete when they contain all the essential amino acids in sufficient quantities and ratios to meet the body’s needs. The proportions of linoleic acid and alpha-linolenic acid in one tablespoon (15 ml) per day of hemp oil easily provides human daily requirements for EFAs (essential fatty acids).

What could be accomplished if hemp were being grown in large quantities all over the world for fuel, for clothing, for paper, etc? How many could we feed with all those hemp seeds?

Plastic Production

Who would’ve thought that plastic can be manufactured from cannabis? Well, it can, just like it’s made from other plant matter. Not only that, but cannabis-based plastics are more easily recycled and degrade at a faster rate than traditional plastics. Other bioplastics are created from corn and soy, but hemp does provide distinct advantages over both of them in terms of strength and sturdiness.

The wide-ranging use for bioplastics made from hemp cannot be understated. Everyday items like soda bottles and food packaging could easily be switched to hemp-based plastics, as well as things like piping, furniture, and even car parts. After a while, you’ll be seeing cannabis-based products everywhere you look.

We can stop using as much toxic herbicide and pesticide and restore our soils.

Hemp has been on earth for a long, long time, and for millennia, our ancestral farmers grew it everywhere knew how to take full advantage of it. One of it’s main benefits is it’s role in crop rotation. Until hemp became illegal to cultivate in the early 20th century, farmers regularly planted hemp as a part of their crop rotation. Why? Because it naturally restored the fields for use by other crops through numerous mechanisms:

- It restores vital nutrients into the soil.

- It removes chemicals from the soil (phytoremediation)

- It naturally killed off invasive plant species (weeds) without the use of chemical herbicides.

- It is relatively pest-resistant, so entire hemp crops didn’t need to use pesticides, allowing the field’s soil to be chemical free for the next crop’s planting.

Hemp, too, absorbs co2 and converts carbon dioxide into oxygen and improves the soil on which it is grown. Sometimes used as a “mop crop” and planted on some farms to restore the soil’s nutrients during agricultural crop rotation, hemp has the phytoremediation potential to remove toxins in the soil.

– “Beyond Sustainability: A Thriving Environment“ – By Tim Delaney, Tim Madigan, p.161

Hemp offers some real environmental advantages, particularly with regard to the limited needs for herbicides and pesticides. Hemp is therefore pre-adapted to organic agriculture, and accordingly to the growing market for products associated with environmentally-friendly sustainable production.

– “Trends in New Crops and New Uses“, Purdue University – Edited by Jules Janick and Anna Whipkey.

We can power our coal-powered plants with much lower sulfur pollution (or even none).

In Puerto Rico, they have a problem with Coal Ash being dumped into the landfills as I wrote here.

Coal. A dirty word for many. A cheap source of electrical power for most. And one of the most devastating sources of pollution in the modern world. But we can cut emissions from coal plants by simply adding hemp biomass to the coal being burned.

By blending coal with biomass materials such as hemp, sulfur emissions from power generation can be reduced (by 40%) and less valuable coal that is high in sulfur can remain competitive.

– “Hemp: An Energy Crop to Transform Kentucky and West Virginia ” – Katherine M. Andrews, Ph.D.

Even more exciting is the prospect of biocoal, a complete alternative to replace traditional coal with almost no sulfur emissions at all . Currently, most biocoal is made from wood, but as we know hemp has a higher cellulose content (57-77%) than wood (38-49%) it stands to reason that as we begin to grow hemp more efficiently and in more abundance, that we could eventually derive more cost productive and efficient biocoal from hemp.

We can reclaim land destroyed by pollution, radiation, and toxic wastes.

Hemp is a member of an elite class of hearty plants that can naturally extract and filter horrible toxins and pollutants for the worst disasters in the world, even radioactive soils. This is a process of soil recovery known as phytoremediation.

Why use hemp as a phytoremediator?

- High biomass which is unaffected by pollutants

- Root can grow up to 8 feet below ground

- Low growing cost

- Quick growing season

- Full maturation in 180 days

- Good accumulator from air and soil

- Contaminated products can be used for industrial purposes: Biodiesel fuels, industrial lubricants and varnishes, insulation, construction materials, paper, clothing, food and plasticized or composited materials for a variety of uses.

– “Hemp (Cannabis sativa L.) as a phytoremediator“, Colorado State University 2012 – Laura Cascardi

Lastly, a number of studies have identified industrial hemp as a top candidate in bioremediation, especially phytoextraction of heavy metals from industrially contaminated soils. Hemp has been used to process greywater in Australia, extensively tested in Europe for the removal of heavy metals from soil, including cadmium, lead, copper, zinc, and nickel often associated with mining, used for the cleanup of polycyclic aromatic hydrocarbons at a site in Hawaii, and cultivated on radionuclide-contaminated soils at the Chernobyl nuclear reactor site.

– “Illegally green: Environmental Costs of Hemp Prohibition“, The Reason Foundation – Skaidra Smith-Heisters

What do you think about Hemp? Do you think it could or should be a major industry?

For more information please visit the links below in which I sourced from.

http://hempethics.weebly.com/industrial-hemp-vs-cannabis.html

http://www.kinemagazine.com/9-ways-industrial-hemp-can-save-the-world/

Leave a Reply